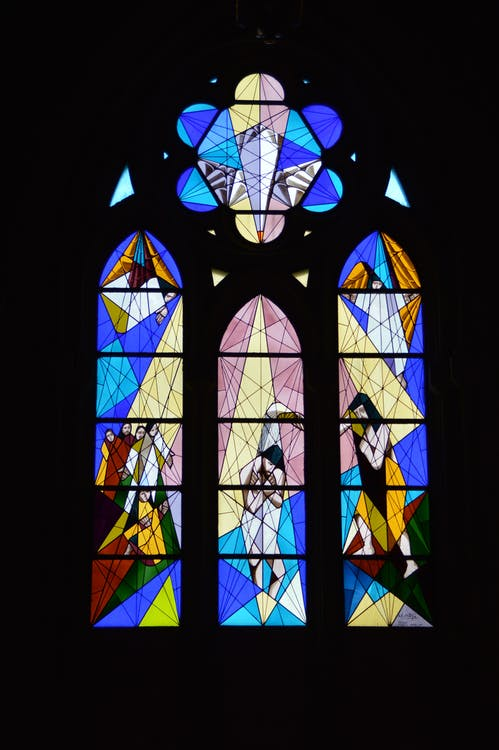

Stained glass is a hand-crafted piece of art that is used to decorate any place. It keeps alive the traditional culture and vibe of the place. Earlier, stained glasses were used in windows and doors of religious places only. But recently, hotels and restaurants use them profusely to give an interesting twist to the interiors.

If you have got your hands on some beautiful stained art glass supplies, then this is your read. In this blog, we will guide you through the top three ways of soldering stained glass. For a newbie, it is necessary to be careful during the whole process.

Three Ways to Solder Stained Glass

You can solder pieces of stained glass together and make a beautiful piece of it. Attaining a stained glass design for your personal space is not a tough ride. But, it definitely needs some expertise and care with the soldering equipment.

1. Foil and Flux Method –

- Set up your materials and switch on your soldering iron. Prepare your copper foil, liquid flux, and solder coil. Connect your soldering iron, place it on its stand, and heat it up.

- Attach your glass pieces by cutting a length of adhesive copper foil. The solder requires another metal on the surface to stick to the glass. The copper foil will stick around the edge of the stained glass.

- Line up the copper foil along the edge of the glass, leaving roughly 18 inches (3.2 mm) on either end. Then, cut the foil carefully.

- Take off the lining from the back of the adhesive foil strip. After you’ve cut the foil into pieces, gently scrape the lining away.

- Apply the copper foil’s adhesive side to the glass’s edge. Place the glass’s edge directly on the center of the copper foil. Then, gently press the foil around the glass’s edges. Wear heavy-duty gloves to prevent any cuts from sharp edges on your hands.

- Repeat until all of your glass pieces’ edges are covered with foil.

- Apply a coat of liquid flux to the entire surface of the copper foil. The flux aids in the permanent bonding of the metal in the solder and the foil.

2. Glass Slit Method –

- Choose a design. Determine what you want to create and how much glass and solder you’ll require. The amounts of both will vary depending on what you’re attempting to create.

- Place the glass on a hard surface above a towel. Brace the glass against something hard, but don’t use too much force or it will shatter.

- Mark the glass. Press your glass cutter down firmly and make a single slit from one side to the other, where you want the glass to break. Be cautious while slitting the glass as it can be dangerous.

- Break the glass along the line carefully. A quick snapping motion with one hand on each side of the line will separate the glass.

- Continue to score and break the glass until you have enough pieces to complete your project.

- Wipe the glass gently to remove any small fragments. Wet sponges or paper towels can be used for the same.

3. Solder Coil Method

- Place your glass pieces in their design position. Allow a very small gap (about 116 inches (1.6 mm)) between the pieces so that the solder can flow into the seam.

- The glass can be assembled on any solid, heat-resistant surface, but metal tables are recommended. This will melt and form the connection between the two bits of glass.

- Unwind nearly 4 inches (100 mm) of solder from the coil. This will melt and fuse the two bits of glass together.

- Keep the soldering iron in your working hand and the soldering coil in the other hand.

- Place the unrolled solder tip above the copper foil. Maintain a solder height of at least 12 inches (13 mm) above the foil. Allow the melted solder to fall into the seam between the glass pieces.

- Connect the soldering iron tip to the unrolled solder tip. It will instantly start to melt the solder, which will fall into the seam.

- Maintain the same position with your hands: one holding the solder and the other holding the soldering iron up to it. While the solder spills down onto the glass, work your way along the seams.

- When you come to the end of the seam, remove the soldering iron tip. A continuous line of solder should be visible along the intersection of the two sheets of glass. The glass is now permanently and strongly bonded together.

Concluding…

Concluding…

So, those were some easy methods of soldering stained glass. Hope you find them easy too. During the entire process (irrespective of method), wear heavy-duty gloves to protect your hands from cuts and scratches. Make sure you do not hold the solder where it is extremely hot.

It is very important to use high-quality and safe glass art tools during the soldering process to prevent injuries. For any guidance on the right tools and equipment contact our team.